|

SW-MPL vertical planetary stirring machine is composed of motor, decelerator, transmission device, shell of tank and slewing bearing. It can evenly and thoroughly mix and discharge all the constituents within a short time. Also it has small occupation area and low energy consumption.

This mixing machine is used during the mixing process of producing refractories, glass, ceramics, concrete and so on. Specially designed mixing device makes the mixing time shorter and more thoroughly. The mixing blade is resistant to wear. Flexible coupling and hydraulic coupler(optional attachment) can effectively protect the transmission system from overload shock. The big-size access door is easy to maintain and clean. We have high-pressure cleaning device and moisture tester for you to choose.

Product characters:

It has both revolution and rotation so the motion trail is complicated. It is with strong force, low wear and can finish mixing fast. It can meet the need of all kinds of large building, precast factory, port and road construction. It has the following characters:

1. The motor and decelerator apply an upper supporting type, so it’s easy to maintain and clean.

2. Materials have no direct contact with the transmission part, so there are no problems such as wear-out and leakage.

3. It is used during the mixing process of producing refractories, glass, ceramics, concrete and so on.

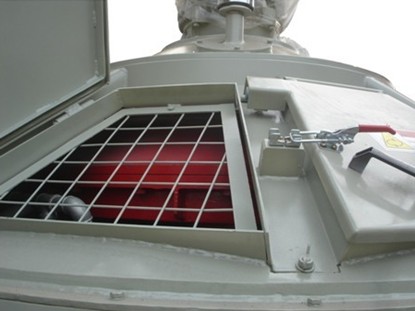

The access door safety device:all the safety switches on the access door are of high reliability and high sensitivity, which is safe and easy to maintain.

Observing viewport:there is an observing port on the access door, through which,we can observe the mixing process without cutting off the electricity. Observing viewport:there is an observing port on the access door, through which,we can observe the mixing process without cutting off the electricity.

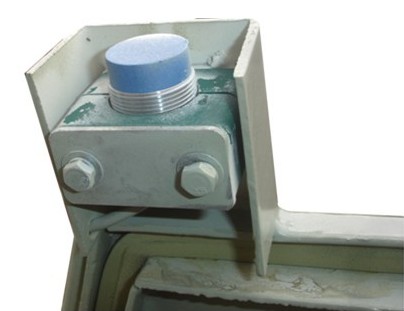

Discharging device:according to customers’ requests, we have two ways of controlling the discharging door--Pneumatic, hydraulic. You can open three discharging doors at most. There is a sealing device on the discharging door to ensure the firm sealing and reliable control.

The mixing device:The planetary shaft of the blade revolves in the mixing cylinder. It can squeeze and overturn the materials to make enforceable mixing.

sprinkler:there is a specially designed sprinkler on the spray pipe. It comes out in a spray form, with a larger area and makes the mixing more evenly.

parameters:

|

parameters |

Model |

|

|

MP

250 |

MP

330 |

MP

500 |

MP

750 |

MP

1000 |

MP

1500 |

MP

2000 |

MP

2500 |

MP

3000 |

|

Discharging capacity (L) |

250 |

330 |

500 |

750 |

1000 |

1500 |

2000 |

2500 |

3000 |

|

Feeding capacity(L) |

375 |

500 |

750 |

1125 |

1500 |

2250 |

3000 |

3750 |

4500 |

|

Discharging capacity (kg) |

600 |

800 |

1200 |

1800 |

2400 |

3600 |

4800 |

6000 |

7200 |

|

Diameter of mixing tube (mm) |

1300 |

1540 |

1900 |

2192 |

2496 |

2796 |

3100 |

3400 |

3400 |

|

Stirring power (kw) |

11 |

15 |

18.5 |

30 |

37 |

55 |

75 |

90 |

110 |

|

Unloading hydraulic power (kw) |

2.2 |

2.2 |

2.2 |

2.2 |

3 |

3 |

4 |

4 |

4 |

|

planetary/mixing blade (nr) |

1/2 |

1/2 |

1/2 |

1/3 |

2/4 |

2/4 |

3/6 |

3/6 |

3/9 |

|

A side scraper (nr) |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

|

Drain separator |

--- |

--- |

--- |

1 |

1 |

1 |

2 |

2 |

2 |

|

Weight of mixing machine (kg)<, /SPAN> |

1200 |

1700 |

2000 |

3500 |

6000 |

7000 |

8500 |

10500 |

11000 |

|

size

(L×W×H)mm |

1570

×

1480

×

1750 |

1862

×

1850

×

1855 |

2220

×

2071

×

1880 |

2550

×

2295

×

2195 |

2893

×

2606

×

2217 |

3223

×

2906

×

2425 |

3625

×

3235

×

2630 |

3893

×

3555

×

2695 |

3893

×

3555

×

2975 | |